The plasma-facing components of the divertor in a magnetic confinement fusion device such as WEST, and later ITER, consist of tungsten elements assembled onto a copper alloy cooled by water circulation. These centimeter-sized, parallelepiped-shaped elements line the bottom of the vacuum vessel and are capable of extracting thermal fluxes of up to 10 MW/m² continuously. The sharp edges of these components can, under certain conditions, be exposed to much higher fluxes and become points of weakness. A new innovative concept proposes an alternative geometry to reduce sharp edges and enhance the robustness of these components against the plasma.

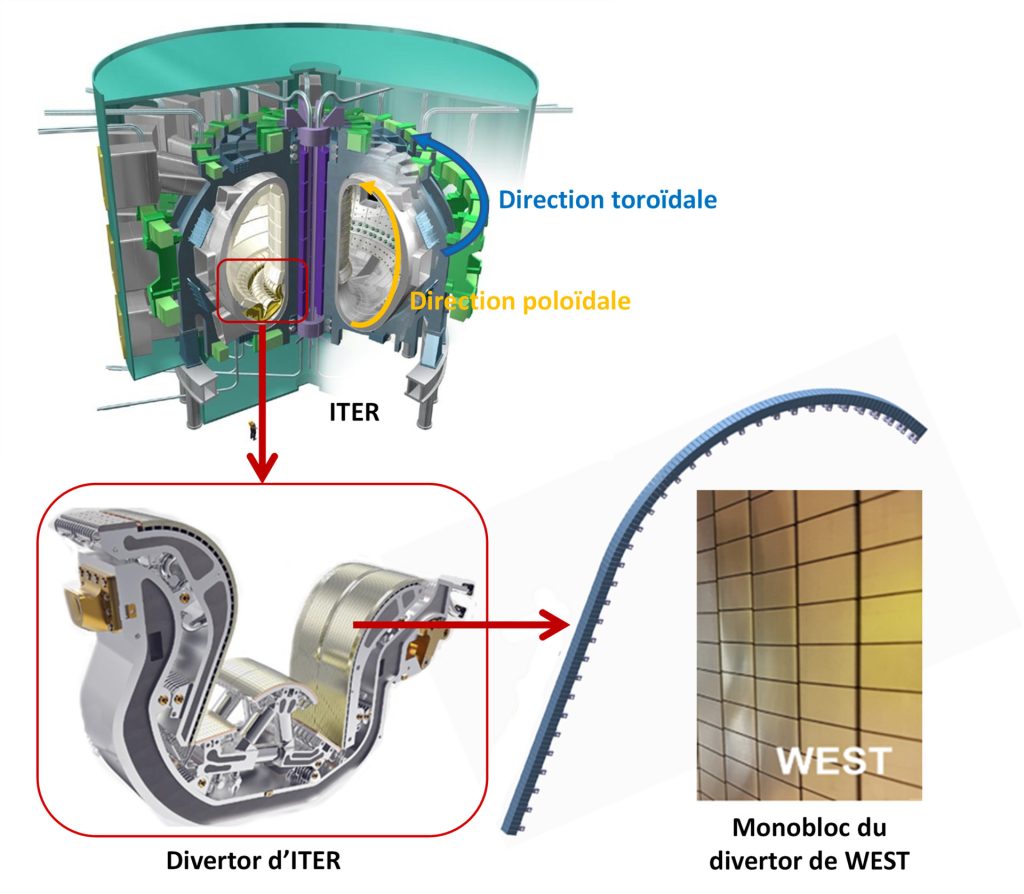

In a tokamak, the divertor’s plasma-facing components (PFCs) are those exposed to the most intense heat and particle fluxes, and their resistance impacts the maximum performance achievable by the plasma. In ITER, they will be able to withstand heat fluxes of around 10 MW/m² continuously and up to 20 MW/m² for a few seconds. The design of the ITER divertor PFBs (Figure 1) is the most resistant developed to date. Currently being tested in WEST and also adopted for the future divertors of the JT-60SA tokamak in Japan and the DTT tokamak in Italy, it consists of tungsten components, called “monoblocks,” assembled in the poloidal direction on a copper alloy (CuCrZr) tube actively cooled by water. This solution allows the heat deposited at the point of impact of the magnetic separator, which runs in the toroidal direction, to be distributed over a maximum number of CFPs. The monoblocks are 12 mm in size in the poloidal direction and 30 mm in the toroidal direction. These small monoblocks are spaced approximately 0.5 mm apart in each direction to accommodate the curved shape of the ITER divertor (Figure 1) and the non-uniform thermal expansion expected when heated by the plasma.

Figure 1: An ITER divertor cassette. The inset shows a close-up view of the WEST divertor highlighting the sharp edges of the monoblocks.

In 2013, the ITER Organization asked the CEA/IRFM to analyze the consequences of tungsten divertor profiling, in particular the heating of the sharp edges of the monoblocks during steady-state and transient phases (Edge Localized Modes – ELMs) in order to assess the risks associated with tungsten recrystallization, exceeding the cooling capacity of the system, and tungsten melting. The purpose of the study was to assess these risks across the full range of assembly tolerances.

The study revealed new theoretical phenomena that had not been previously imagined and were subsequently demonstrated to be real in experiments [1]. During ELMs, all sharp edges of the monoblocks, even those shaded by the toroidal bevel, are exposed to intense fluxes and can melt. These instabilities cause ions with energies of several keV to impact the sharp edges due to their Larmor radius (~2 mm), which allows them to reach magnetically shadowed surfaces. As a result, the limit of 0.5 MJ/m2 per ELM must be reduced to 0.1 MJ/m2 in order to prevent the melting of these sharp edges. Since tungsten cracking has already been observed in WEST during disruptions corresponding to this energy level, ITER has decided to install magnetic coils to mitigate ELMs from the first day of operation.

Building on the experience of this fruitful collaboration, the CEA/IRFM has developed a concept within the framework of EUROfusion that could eliminate the sharp edges of CFPs [2].

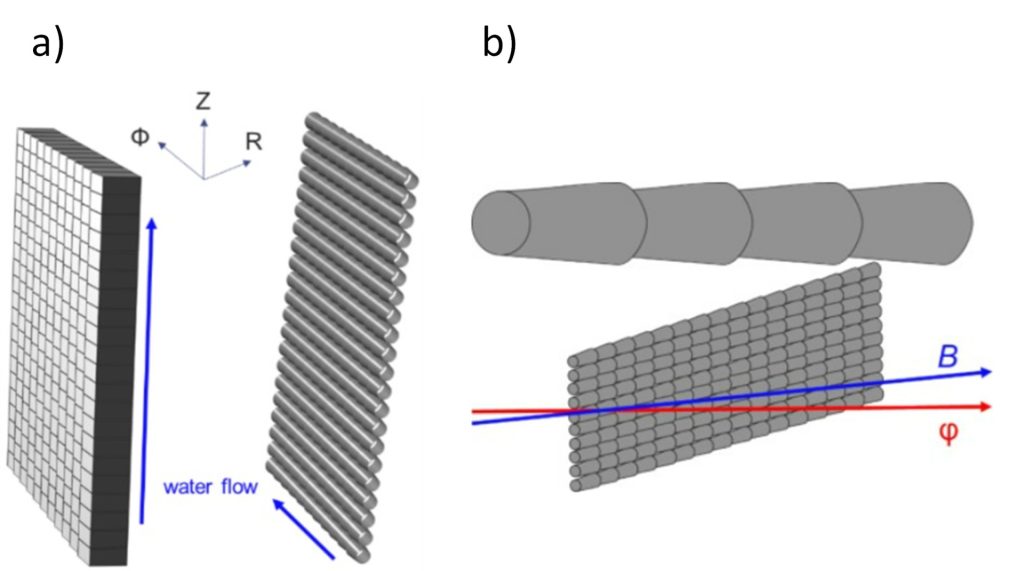

Inspired by Provençal roofs covered with Roman tiles (Figure 2), the idea is to orient the CFPs not purely in the poloidal direction but in a direction between the poloidal and toroidal directions. The CFPs would consist of tungsten cones assembled on CuCrZr tubes. Initial calculations show that these CFPs would not heat up more than monoblocks under identical flow conditions, and perhaps less, depending on the thickness of the tungsten armor. These CFPs, as seen by the plasma, would have no sharp edges, thus alleviating the problem of ELMs. A very important result of the study is that such CFPs would be virtually immune to assembly tolerances. Misalignments of several mm, instead of the 0.3 mm specified in ITER, would be acceptable, which considerably reduces the cost and complexity of assembly.

Figure 2:

(a) Diagram of the ITER outer divertor vertical target on the left, and the new tube concept on the right.

(b) Sketch of the alternative divertor design. The cooling tubes are shielded by conical tungsten balls, allowing them to be bent to fit the desired shape of the divertor. The pitch of the conical balls is greatly exaggerated for clarity. In reality, with radial pitches of only 0.5 mm between the leading and trailing edges of balls approximately 2 cm in diameter, these radial pitches will be barely noticeable to the naked eye.

These initial investigations, based solely on physical considerations, open up new perspectives and numerous topics for study, such as optimizing the alignment angle in terms of heat dissipation and critical flow, the manufacturability of such a geometry, dimensioning for electromagnetic forces, etc. These issues will be addressed during future development with the aim of manufacturing a prototype and subjecting it to high thermal flux tests.