A high-precision laser cleaning solution has been deployed to maintain the operational condition of components exposed to plasma in the vacuum vessel in the WEST tokamak.

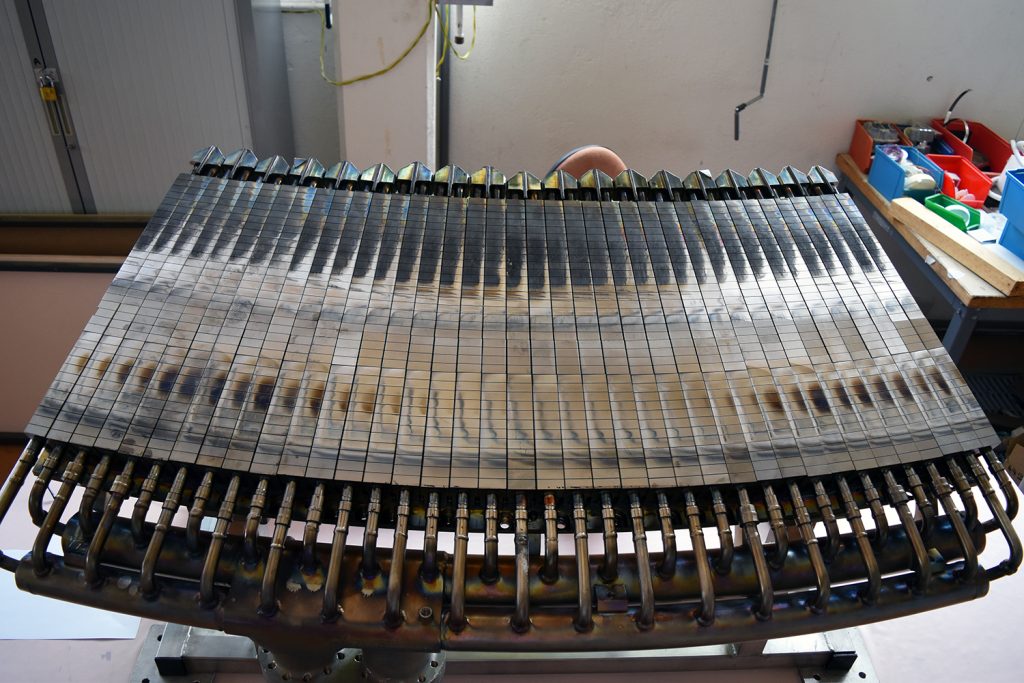

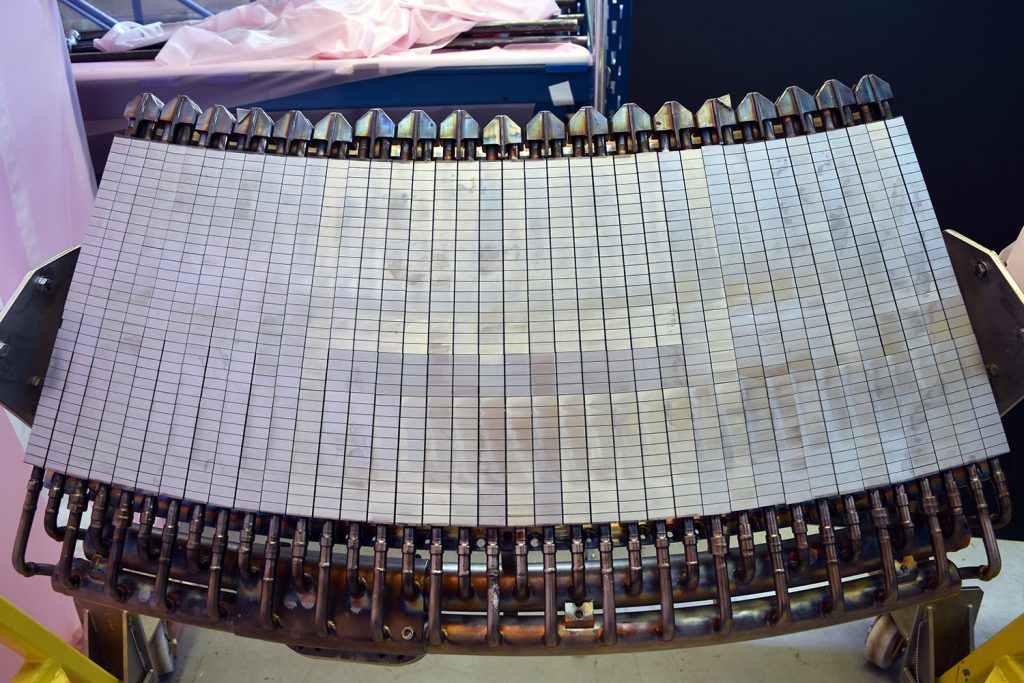

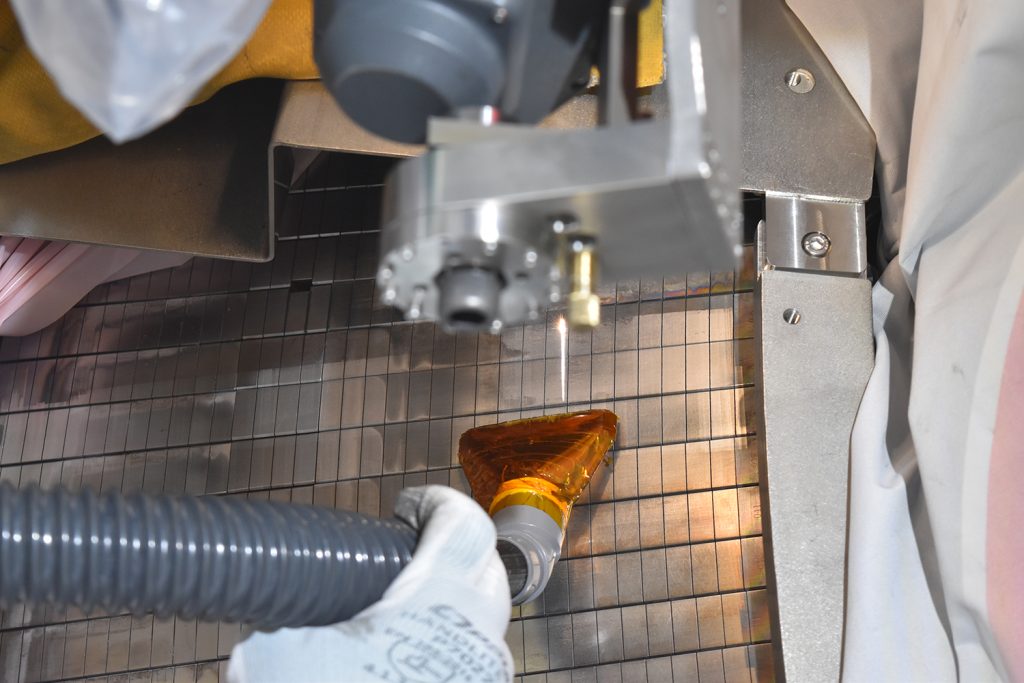

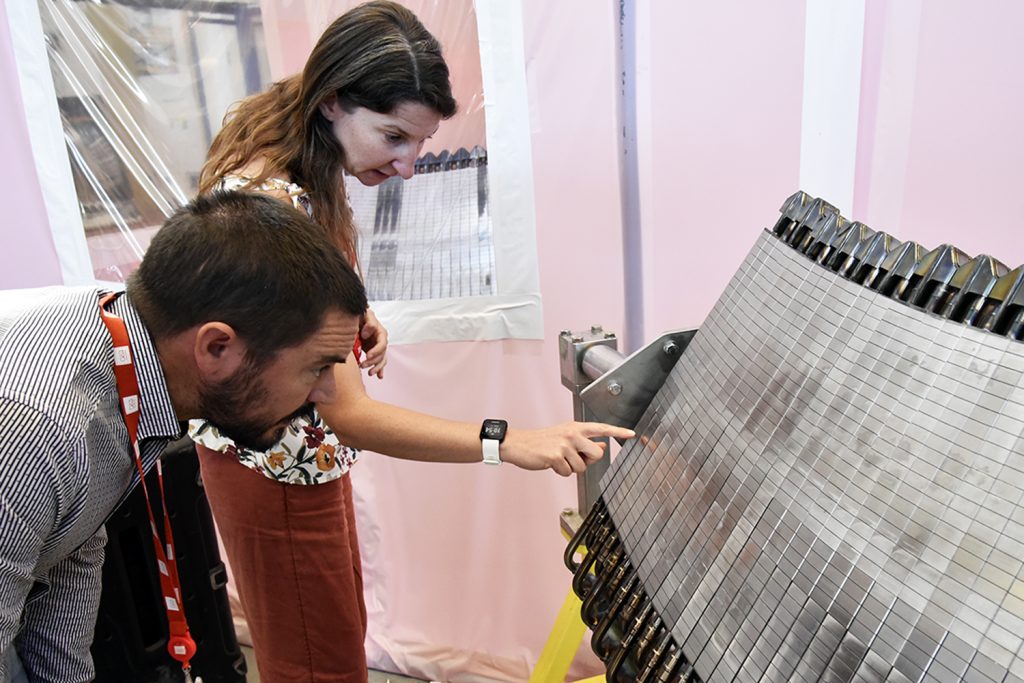

After more than a year of testing and validation, a compact, controlled solution was chosen to accurately remove impurity deposits (mainly W, Fe, Cu, and B) resulting from the interaction between the plasma and the vacuum chamber, without damaging the tungsten surface. The operation was carried out directly in the vacuum chamber, but also outside it, by extracting sections of components. This first successful intervention marks a key step towards the potential automated and robotic use of this technology.

This success opens the door to exploring cutting-edge approaches to optimizing maintenance and extending the service life of fusion research equipment, as well as reducing the rate of plasma disruption, which often causes experiments to be stopped prematurely.

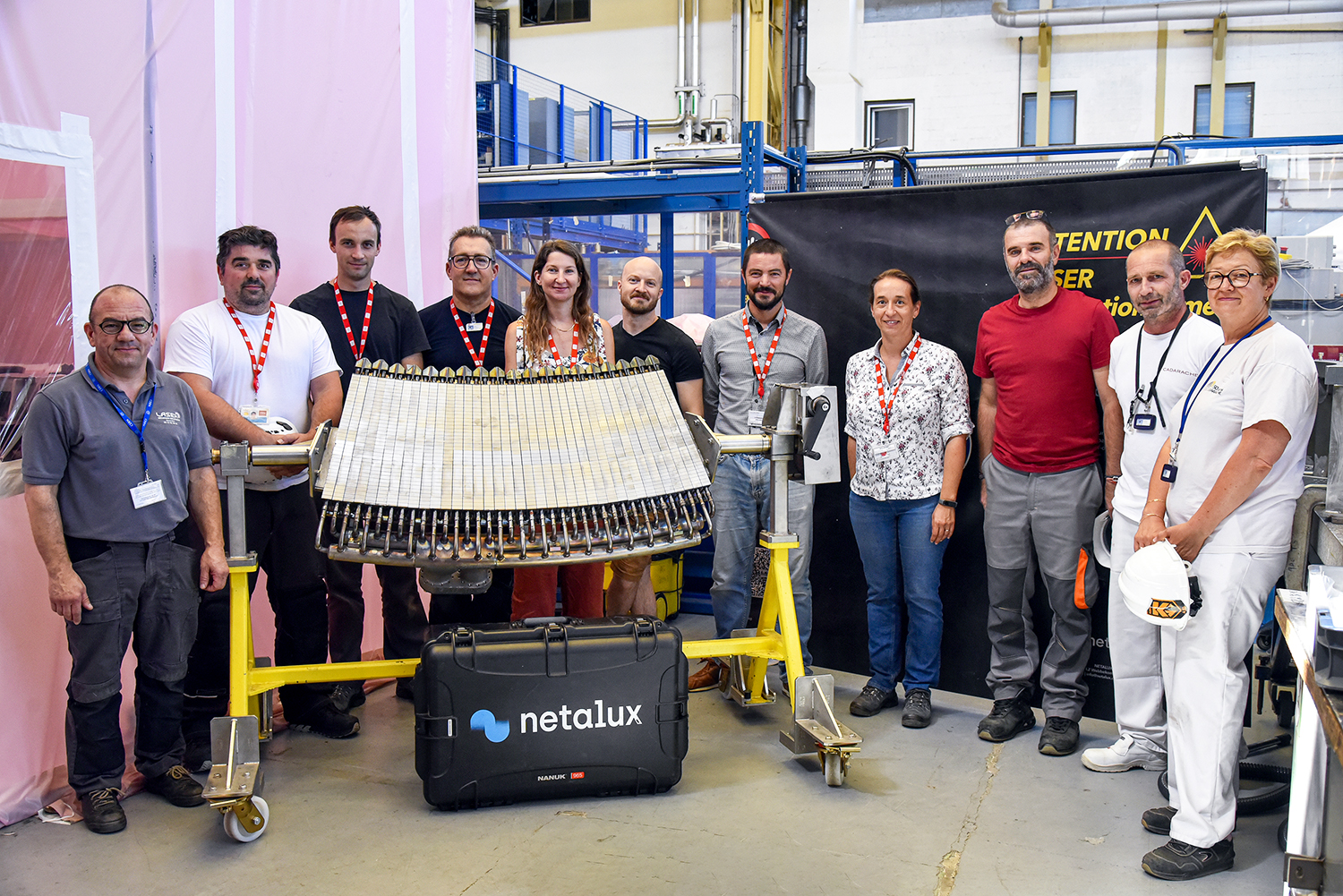

The result of collaboration between IRFM teams and the companies Netalux and Décapage Solutions, this breakthrough demonstrates the value of cooperation between in-house expertise and specialized partners.