Controlling the tritium cycle is one of the major scientific challenges for future fusion power plants and a key issue for certain fourth-generation fission reactor designs. The recently completed European TITANS project, coordinated by CEA-IRFM, has brought together a consortium of 21 partners since 2022 to understand the behavior of tritium throughout its life cycle. At the crossroads of materials science, biology, the environment, and modeling, TITANS has produced numerous results that illustrate the vitality of European transdisciplinary research in addressing a key challenge for the energy of the future.

Since 2022, the TITANS project (Tritium Impact and Transfer in Advanced Nuclear reactors [1]) has brought together 21 European partners around a common goal: to address the challenges posed by increased levels of tritium in tomorrow’s nuclear reactors (Generation IV) and future fusion power plants. This transdisciplinary project, coordinated by CEA-IRFM, brings together international experts in materials science, process engineering, biology, environmental science, and modeling. The consortium’s activities aim to provide answers to the major challenges posed throughout the tritium life cycle:

- disseminating knowledge and training the next generation of researchers

- minimizing sources and limiting releases into the environment [2]

- assessing the biological impact on living systems [3,4]

The consortium has produced 13 publications in international journals and has established itself as a benchmark thanks to flagship initiatives such as the creation of the Tritium School. The fourth edition of this school will be held in Madrid in March 2026, following the 2024 edition in Marseille, which attracted nearly 450 participants (photo below).

as part of the TITANS project

An example of the activities and results produced within TITANS concerns the evaluation of tritium behavior (permeation and retention) in certain materials of interest, in particular Eurofer. Eurofer is a steel derived from a grade developed for fast neutron fission reactors and modified in the context of fusion to develop rapid deactivation properties. It is being considered as a structural material for components that will produce tritium in fusion power plants and be responsible for extracting the power generated by fusion reactions. It could be used at high temperatures (up to 550°C) to achieve high electricity production yields. These temperature ranges greatly increase the mobility of hydrogen in materials, exacerbating the problem of tritium permeation. Some tritium-producing blanket designs use a liquid metal, lithium-lead (LiPb), as a tritium-producing material. Prolonged exposure to LiPb causes significant corrosion of Eurofer, which can be minimized by protecting the substrate with anti-corrosion coatings. The impact of this protective layer on trapping and permeation was evaluated within the TITANS project by comparing permeation under different Eurofer surface conditions (with/without corrosion barrier, before/after exposure to LiPb).

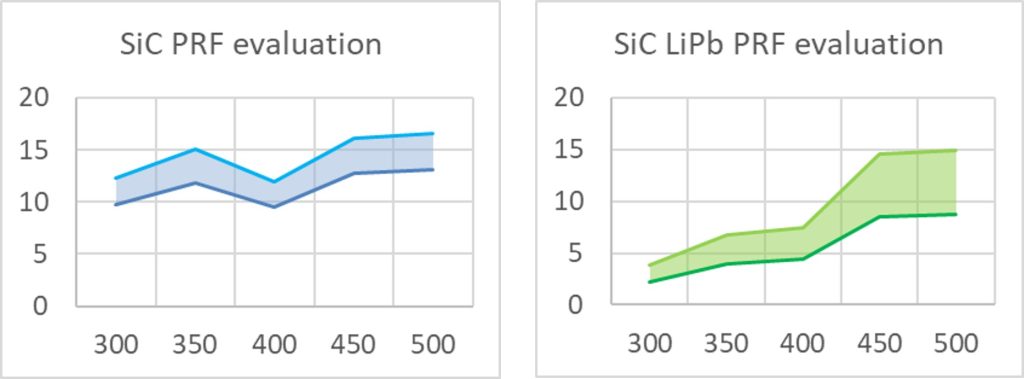

This activity initially consisted of developing and testing, on CIEMAT’s Corrosion Loop for Liquid Metal Experiments (CICLO) [5], the corrosion barrier performance of various coatings such as alumina (Al2O3) and silicon carbide (SiC). The SiC coating proved to be the most effective, providing efficient protection for Eurofer after 1,500 hours of exposure to LiPb at 450°C. In a second step, the impact of corrosion barriers on permeation was studied. This impact can be evaluated by determining the ratio, called the Permeation Reduction Factor (PRF), between the permeation of the material without and with the corrosion barrier. A high PRF indicates a high ability to block permeation. After extraction and removal of LiPb residues, deuterium permeation from 100 to 550°C was evaluated on the CEA-IRFM Hypertomate* test bench [6]. The results show that, in terms of permeability, Eurofer exposed to LiPb is identical to bare Eurofer (the corrosion layer has no influence on permeation, its PRF is equal to unity). On the other hand, the SiC anti-corrosion barrier does impact permeation. PRF measurements show values between 10 and 16 on Eurofer samples with SiC coating not exposed to LiPb and PRFs between 2 and 10 after exposure to LiPb for 1000 hours (figure below). These results indicate a decrease in the effectiveness of these anti-corrosion barriers in terms of permeation when exposed to LiPb, particularly at temperatures below 400°C. These results highlight the potential of SiC as a corrosion and permeation barrier, but also its limitations when exposed to LiPb for prolonged periods. They will be supplemented by tritium experiments that have begun at the CEA-Joliot tritium laboratory.

in °C on a Eurofer sample with SiC coating not exposed to LiPb (left)

and after exposure to LiPb for 1000 hours in CICLO (right).

The TITANS project was completed at the end of August and illustrates the strong momentum of the DRF around tritium-related activities. The results of TITANS will be presented orally at the major IAEA conference on fusion (FEC 2025) in mid-October in China.

*Hypertomate (HYdrogen PERmeation in tokamak relevant MATErials) is a test bench that measures hydrogen permeation and obtains transport parameters in materials.

References

[1] https://titans-project.eu/

[2] A. Vankrunkelsven et al., Fusion Science and Technology (2024) – DOI: 10.1080/15361055.2024.23611981

[3] M. Ferreira et al., Environmental Pollution (2025) – DOI : 10.1016/j.envpol.2025.127002

[4] F. Larese Filon et al., Environmental Pollution (2025) – DOI : 10.1016/j.envpol.2024.125327

[5] E. Carella et al., Applied Sciences-Basel (2022) – DOI : 10.3390/app12063104

[6] F. Montupet-Leblond et al., Nuclear Fusion (2022) – DOI : 10.1088/1741-4326/ac6e74